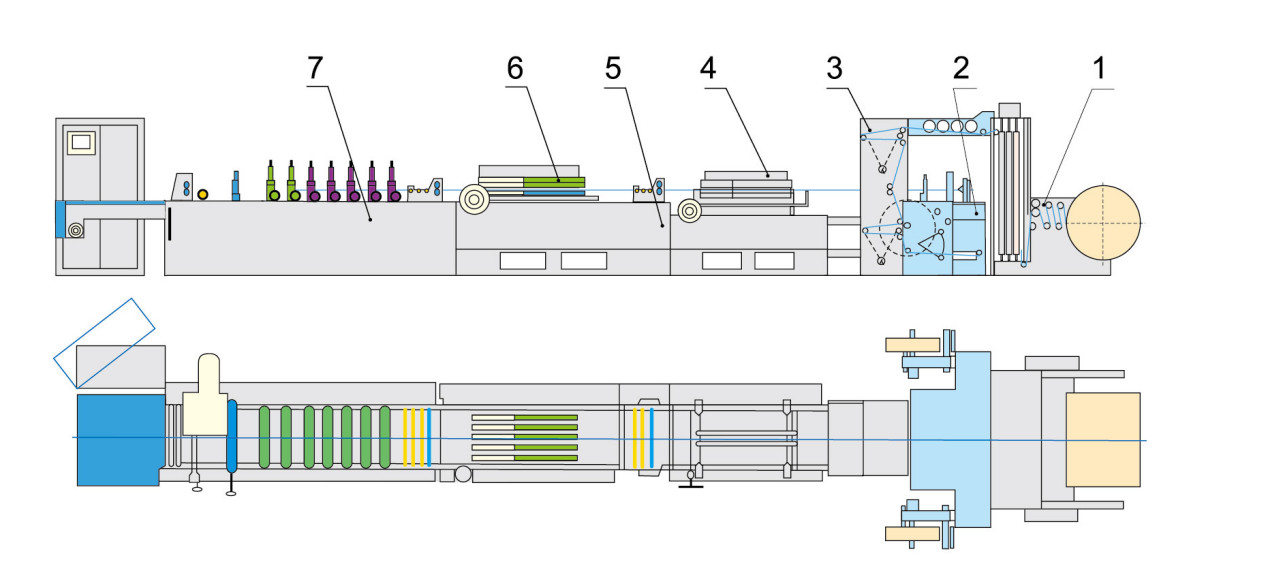

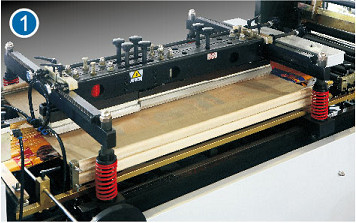

1.Warping unit

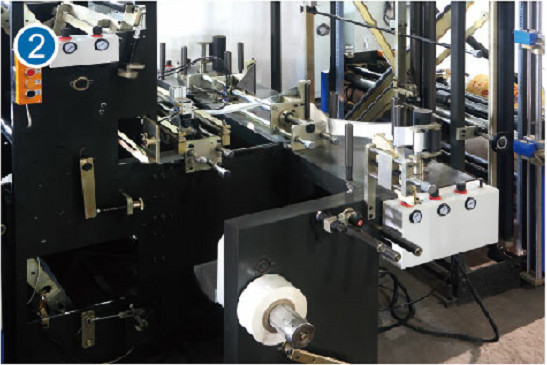

2.Auxiliary bag-standing unit

3.Stand parallel tension unit

4.Zipper press seal tension unit

5.3th servo unit

6.Side-heat seal unit

7.Horizontal heating unit

1.The whole machine adopts imported PLC, and the HMI is centrally controlled.

2.Automatic constant tension control, LPC automatic deviation correction, AC frequency conversion constant speed automatic feeding.

3.Imported three servo drag control.

4.The upper and lower sealing pressure AC variable frequency motor drive.

5.The temperature of the hot pressing knife is adjusted by PD, which is automatically controlled without contact, and the HMI is centrally set.

6.Pneumatic multi-function automatic punching, automatic collection of edge material removal, equipped with static electricity elimination device.

7.Temperature: adjustable from 0 to 300 °C, non-contact control, centralized setting on the touch screen.

8.Counting: Quantity and batch number are automatically accumulated, with preset function.

9.Working method: custom-length bag, photoelectric tracking bag, stand-up bag, zipper bag.

10.Punching method: continuous, interval, stop, and punching time can be preset.

11.Double delivery method: 1 to 6 times delivery.

12.Batch delivery function: The work unit has the batch delivery function, it can be preset.

Zipper Ironing Part

Zipper & Trimming Part

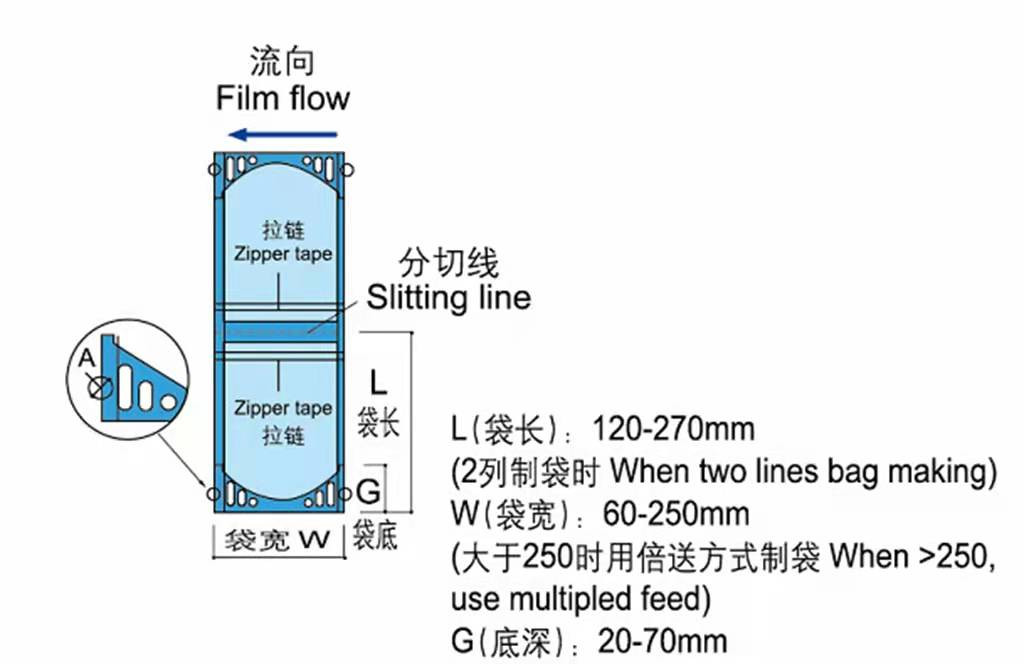

Remark: skip feeding function is available for bag making length that over 320mm

-Provide Solutions

According to customer’s bag size and shape, to set out corresponding plan

-Product Development

Partial brand can be customized if clients need

-Customer Confirmation

Put machine into production

-Machine Test

Test trial until quality acceptance

-Packaging

Anti - dust & plastic film

-Delivery

By sea.